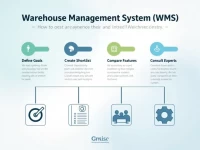

Key Factors for Selecting a Warehouse Management System

Choosing the right Warehouse Management System (WMS) is crucial for businesses. This article presents key project milestones, guidance on creating a shortlist of vendors, comparison discussion techniques, and expert implementation recommendations. It aims to assist decision-makers in finding the most suitable system to optimize operations and reduce risks.